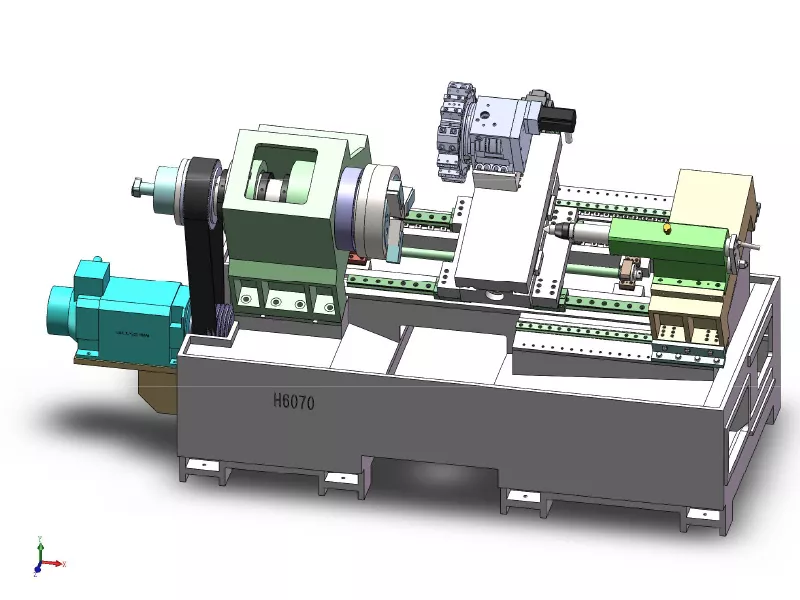

H6070 Slant Bed CNC Lathe

| Availability: | |

|---|---|

With the rapid development of the manufacturing industry, CNC machine tools as the core equipment of modern manufacturing, its processing efficiency and cost control is more and more attention by enterprises. Row knife CNC lathe as one of the important models, in order to improve processing efficiency and reduce production costs have significant advantages.

gang type CNC lathe adopts multi-station row tool structure, can complete multiple processes in one clamping, reducing the workpiece multiple clamping and positioning time. Compared with the traditional lathe, the machining efficiency of CNC lathe with row of knives has been greatly improved. In terms of cost control, row cutter CNC lathe also performs well. Firstly, due to its high processing efficiency, more workpieces can be processed per unit of time, thus reducing the production cost per unit of product. Secondly, the tool change of row cutter CNC lathe is fast and convenient, which reduces the non-productive time and lowers the labour cost. Again, for the same size, the price of gang style CNC lathe is lower than turret lathe.

CNC Control System Brand

GSK988TA is Standard

Optional:

HNC-808D-10G

Syntec 22TA

FANUC 0i-TF plus

Siemens 828d

Mitsubishi

Application

● Precision parts

● Mechanical parts

● Hardware parts

● Hand tools

● Medical parts

● Clock & watch parts

● Optical parts

● Auto parts

● Bathroom parts

● Bike accessory

Automatic Parts Feeder

Adopting hydraulic system drive, the feeding force is large, suitable for larger diameter and heavier bar material feeding. It has the advantages of good stability and high reliability.

● Improve production efficiency

● Reduce production cost

● Improve production safety

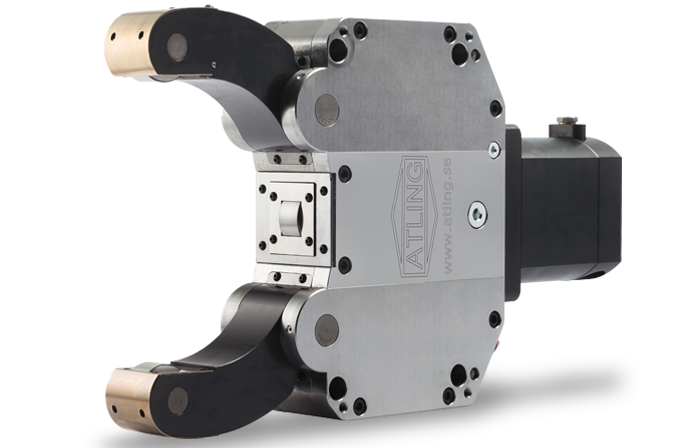

Bar Catcher

Utilizes compressed air as a power source to achieve the splicing function.

● Realizes continuous machining

● Convenient workpiece handling and storage

Automatic Loading Truss

Gripping mode: gripping, handling, lifting, turning

Suitable for:Hardware fittings, plastic parts, 3C electronic parts, automobile parts, electronic and electrical parts, furniture and home appliance parts.

Robot

High precision and high beat rate: with a repeatability of ±0.02 mm and a maximum beat rate of 4 m/s, the robot can efficiently transport parts, increasing productivity by 20% - 40% in machine tool loading and unloading.

Robot loading and unloading: a production line, a single investment can meet the needs of multi-variety production.

Low investment and quick return: one robot can realize single or multi-station loading and unloading.

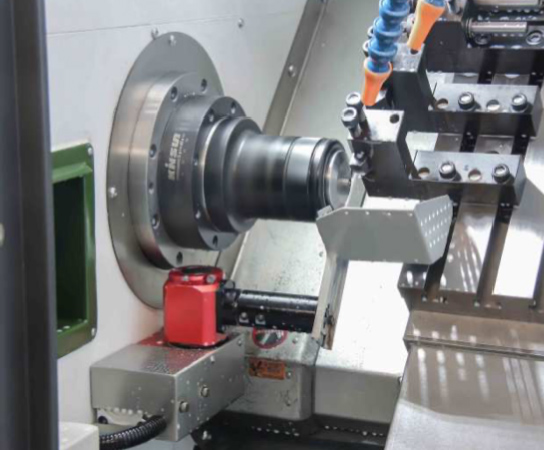

Turret

The power cutter disc indexing adopts servo cutter disc.

Can cut in forward and reverse directions.

Two-way nearby tool change, fast speed and high efficiency.

High positioning accuracy and high repeat positioning accuracy.

High rigidity and good stability

8 T Servo Turret

12T Power Turret

12T Power Turret With Y Axis

Automatic lubrication

The automatic lubricator automatically delivers lubricant to the X- and Z-axis guide and screw to ensure smooth operation at all times.

In case of oil shortage, an alarm is issued and the machine stops automatically.

Clamping

Collet

Chuck

Size: 6", 8", 10", 12", 15"

Type: solid/ hollow

Jaw: 2/3/4Jaws

Indexing Chuck

| Technical data | |

| Maximum swing diameter on bed | Φ600 mm |

| Maximum processing disk diameter | Φ500 mm |

| Maximum processing shaft diameter | Φ350 mm |

| Maximum workpiece length | 580 mm |

| Spindle through hole diameter | Φ82 mm |

| Spindle maximum speed | 2000 rpm |

| Spindle motor power | 15 Kw |

| X/Z axis travel | 320mm/700mm |

| X/Z axis rapid speed | 20/20 m/min |

| Spindle box gear speed | A gear 50-500/B gear 150-1500 / |

| gang-type tool holder/turret | 8P servo turret / |

| Tailstock sleeve diameter | Φ75 |

| Tailstock sleeve travel | 150mm |

| Tailstock sleeve taper | MT5 |

| Spindle outer circle radial runout | ≤0.005 mm |

| Positioning accuracy X axis | ≤0.01 mm |

| Positioning accuracy Z axis | ≤0.01 mm |

| Repeatability X axis | ≤0.01 mm |

| Repeatability Z axis | ≤0.01 mm |

| Turning workpiece roundness torrance | 0.01 mm |

| Turning workpiece consistency in longitudinal section | 0.01/75 mm |

| Bed layout | Overall inclined bed |

| Machine weight | 4500 Kg |

| Machine overall dimensions (LxWxH) | 2920X1900X1750 mm |

Standard Configuration:

GSK/HNC System,

8 Position hydraulic servo turret,

A2-8 Spindle,

12"solid chuck,

#MT5 Tailstock,

Local ballscrew,

Hiwin linear guideway,

Protection cover,

Coolant and recycle,

15KW Main motor power,

370W cooling pump.

| Optional configuration | ||

| CNC SYSTEM | Syntec system 21TA |  |

| Syntec system 22TB | ||

| Fanuc system Oi-TF-plus | ||

| Siemens system 828d | ||

| Fanuc system Oi-TF-plus with C axis | ||

| Siemens system 828d with C axis | ||

| TURRET | 12 Position turret |  |

| 12 Position power turret | ||

| Y axis | ||

| CHUCK | 15" Solid chuck |  |

| 12" Indexing chuck | ||

| DRIVE | 15KW Electro-spindle |  |

| POWER HEAD AND TOOL HOLDER | ER25 (2+2) power head |

|

| ER25 (3+3) power head | ||

| ER (4+4) power head | ||

| ER20 power head | ||

| ER25 power head | ||

| Hex power head | ||

| ER25 2 power head | ||

| ER25 3 power head | ||

| ER25 side 2 power head | ||

| ER25 side 3 power head | ||

| Square tool holder | ||

| Round tool holder | ||

| BMT55 90⁰ Powe tool Holder | ||

| BMT55 0⁰ Powe tool Holder | ||

| BMT40 90⁰ Powe tool holder | ||

| BMT40 0⁰ Powe tool holder | ||

| Fly wheel | ||

| Ball machine | ||

| DRIVE COMPONENT | Hiwin ballscrew |  |

| ACCURACY | Renishaw tool presetter |  |

| PROTECTION | Auto door |  |

| Auto roof | ||

| AUTOMATION | Part catcher |  |

| Robot | ||

| Automatic Loading Truss | ||

| CLEANER | Chip conveyor |  |

| Oil skimmer | ||

| WORKPIECES SUPPORT | Follow rest |  |

| COOLANT AND RECYCLE | 500w Cooling pump |  |

| Heat Exchanger | ||

| Cabinet Air Conditioner | ||

Related Products

the perfect solution for your needs