GS350 Two-in-one Turret Lathe

Casting: Because the bed is made of integral casting, the column guideway is 90. tilted layout, with a large bearing cross-section, so there is good rigidity and vibration absorption, the design of high and low guideway can ensure high-precision cutting processing. Avoid the use of special fixtures, better to eliminate the processing errors brought about by the secondary clamping, no need to repeat the positioning, machining accuracy, rigidity enhancement. Shorten the production cycle and reduce the cost.

Main transmission system: The main transmission system of the machine tool adopts AC servo motor, which directly drives the spindle with high-efficiency parallel synchronous belt. It avoids the noise problem caused by the gearbox transmission chain. The front and rear ends of the spindle assembly adopt NSK precision high-speed spindle bearing sets, the most classic layout of high rigidity spindle bearings, and apply appropriate preload, with the best span to support the spindle box, so that the spindle has a high rigidity and high-speed operation capability. The advanced spindle structure together with the perfect process measures to ensure that the main drive system with high rigidity, high precision and high stability.

Feeding system: The machine tool adopts ball screw and linear rolling guideway, with high transmission efficiency and good precision maintenance, which makes the machine tool holder move quickly and stably with high positioning accuracy.

X, Z guide rail adopts linear guide rail form, guide rail friction coefficient is low to ensure that the machine tool X, Z guide rail of high positioning accuracy. X, Z ball screw selection after many times of precision calculations and repeated calibration, to ensure high positioning accuracy and repeatability of positioning accuracy.

Turret: high rigidity hydraulic turret, with high reliability and repeatability.

Translated with DeepL.com (free version)

| Availability: | |

|---|---|

CNC Control System Brand

GSK988TA is Standard

Optional:

HNC-808D-10G

Syntec 22TA

FANUC 0i-TF plus

Siemens 828d

Mitsubishi

Application

● Precision parts

● Mechanical parts

● Hardware parts

● Hand tools

● Medical parts

● Clock & watch parts

● Optical parts

● Auto parts

● Bathroom parts

● Bike accessory

Automatic Parts Feeder

Adopting hydraulic system drive, the feeding force is large, suitable for larger diameter and heavier bar material feeding. It has the advantages of good stability and high reliability.

● Improve production efficiency

● Reduce production cost

● Improve production safety

Bar Catcher

Utilizes compressed air as a power source to achieve the splicing function.

● Realizes continuous machining

● Convenient workpiece handling and storage

Automatic Loading Truss

Gripping mode: gripping, handling, lifting, turning

Suitable for:Hardware fittings, plastic parts, 3C electronic parts, automobile parts, electronic and electrical parts, furniture and home appliance parts.

Robot

High precision and high beat rate: with a repeatability of ±0.02 mm and a maximum beat rate of 4 m/s, the robot can efficiently transport parts, increasing productivity by 20% - 40% in machine tool loading and unloading.

Robot loading and unloading: a production line, a single investment can meet the needs of multi-variety production.

Low investment and quick return: one robot can realize single or multi-station loading and unloading.

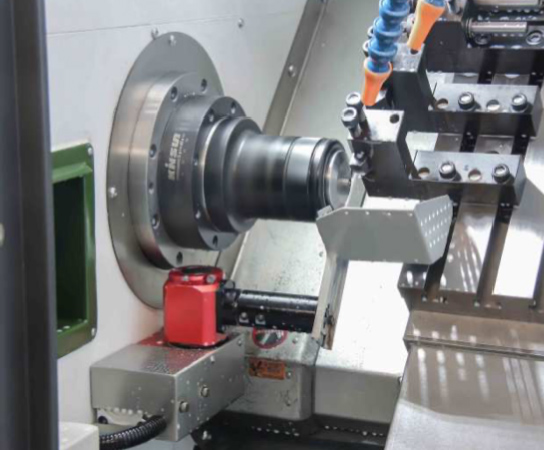

Turret

The power cutter disc indexing adopts servo cutter disc.

Can cut in forward and reverse directions.

Two-way nearby tool change, fast speed and high efficiency.

High positioning accuracy and high repeat positioning accuracy.

High rigidity and good stability

8 T Servo Turret

12T Power Turret

12T Power Turret With Y Axis

Automatic lubrication

The automatic lubricator automatically delivers lubricant to the X- and Z-axis guide and screw to ensure smooth operation at all times.

In case of oil shortage, an alarm is issued and the machine stops automatically.

Clamping

Collet

Chuck

Size: 6", 8", 10", 12", 15"

Type: solid/ hollow

Jaw: 2/3/4Jaws

Indexing Chuck

| ITEM | UNIT | GS350 | ||

| Machining range | Max swing diameter over bed | mm | Φ450 | |

| Max turning diameter (shaft/ disc) | mm | Φ350/Φ350 | ||

| Max turning diameter | mm | 330 | ||

| Max travel of sub spindle | mm | 500 | ||

| Spindle | Spindle type | ISO A2-6 | ||

| Chuck size | 10” solid 10”hollow | |||

| Spindle speed | r/min | 3000 | ||

| Spindle bore | mm | Φ66 | ||

| Bar capacity | mm | Φ52 | ||

| Main motor power | kw | 11 | ||

| Spindle torque | Nm | 143 | ||

| Sub spindle | Sub spindle type | ISO A2-6 | ||

| Chuck size | 10” solid 10”hollow | |||

| Sub spindel speed | r/min | 3000 | ||

| Sub Spindle bore | mm | Φ66 | ||

| Sub spindle bar capacity | mm | Φ52 | ||

| Sub spindle main motor power | kw | 11 | ||

| Sub spindle torque | Nm | 143 | ||

| Feeding | Rapid speed | m/min | Xaxis 20 X1axis 20 Zaxis 20 Z1axis20 | |

| Feeding speed X/Z axis | mm/min | X/Z axis 0-9000 | ||

| Max travel X/Y/Z axis | mm | Xaxis 245 X1axis 245 Zaxis 400 Z1axis400 | ||

| Accuracy | Position accuracy | mm | (X)0.008(Z)0.008 | |

| Repeatability | mm | (X)0.004(Z)0.004 | ||

| Reverse difference | mm | 0.007 | ||

| Processing roundness | mm | 0.004 | ||

| Processing clindericity | mm | 0.012 | ||

| Processing flatness | mm | 0.0135 | ||

| Implementation Standards GB/T16462.4-2007 | ||||

| Turret | Turret type | 12 position | ||

| Tool change type | Any position, servo motor | |||

| Tool change time | s | 0.45/1.45(near/far) | ||

| Square tool holder | mm | 25×25 | ||

| Round tool holder | mm | Max φ40 | ||

| Power head | ER16 | |||

| Machine tool structure | Guideway type | Ball guideway | X axis 35 X1 axis 35 | |

| Z axis 35 Z1 axis 35 | ||||

| Guideway center span | mm | 210/210/310/310 | ||

| X/X1/Z/Z1 axis | ||||

| Screw type | Ball screw | X axis φ3210 X1 axis φ3210 | ||

| Z axis φ3210 Z1 φ3210 | ||||

| The design and manufacture of machine tools conform to ISO international standards. | ||||

| All parts and various measurement units of machine tools conform to the International Unit (SI) standards. | ||||

| Machine tool dimension | L*W*H | mm | 2600×2020×2780 (without chip conveyor) | |

| Weight | kg | 6000 | ||

Standard Configuration

GSK988T system

Linear Guideways

A2-6 synchronous gear spindle

A2-6 synchronous gear spindle

Hydraulic station

10″ Solid hydraulic chuck

12 position power living tool turret

Chip collecting groove

Heat exchanger for electrical cabinet

Warning Light

Machine tool lighting

full loop measurement

Inner sliding door protection

OPTIONAL

MACHINE LAYOUT

the perfect solution for your needs