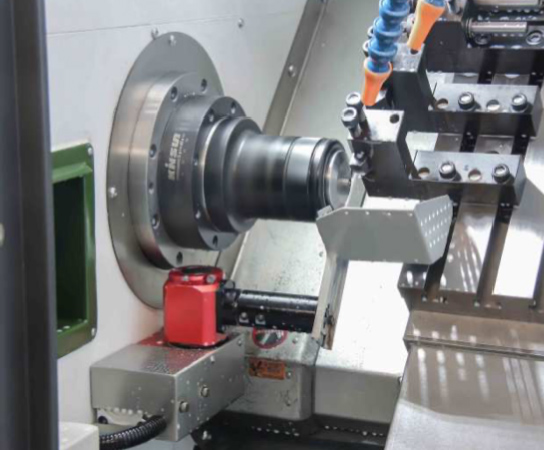

GV400/GV500 Inverted Vertical Combination CNC Turning Center

| Availability: | |

|---|---|

1. Castings: As the bed adopts the whole casting molding, the column guideway 90 ° inclined layout, with a larger bearing cross-section, so there is a good rigidity and vibration absorption, high and low guideway design can ensure high-precision cutting processing. Avoiding the use of special fixtures, it can eliminate the machining errors brought by the secondary clamping, no need to repeat the positioning, machining accuracy is improved, and the rigidity is enhanced. Shorten the production cycle and reduce the cost.

2. Main drive system: the spindle is an electric spindle, which eliminates the external force of the belt link, makes the spindle run more smoothly, reduces the vibration and noise caused by the belt drive, and improves the machining quality. Suitable for low-speed power turning and high-speed finishing requirements, equipped with brake disk and encoder, can be used through the servo device for precise control of the spindle operation, to realize the quasi stop, emergency stop function. It can realize “zero transmission”, faster and more accurate speed control and angular positioning, and can realize highly accurate linkage machining.

3. Feeding system: The machine tool adopts ball screw and linear rolling guideway, which has high transmission efficiency and good accuracy retention, making the machine tool holder move quickly and stably with high positioning accuracy.

X, Z guide rail adopts linear guide rail form, guide rail friction coefficient is low to ensure the high positioning accuracy of X, Z guide rail of the machine tool, X, Z ball screw selection after many times of precise calculation and repeated calibration, to ensure high positioning accuracy and repeatable positioning accuracy.

4. Turret: Adopting high rigidity hydraulic turret designed and developed independently, which has high reliability and repetitive positioning accuracy.

Sub-spindle: The sub-spindle is an electric spindle, which eliminates the external force of the belt link, makes the spindle run more smoothly, reduces the vibration and noise caused by the belt drive, and improves the machining quality. Suitable for low-speed powerful turning and high-speed finishing requirements, equipped with brake disk and encoder.

CNC Control System Brand

GSK988TA is Standard

Optional:

HNC-808D-10G

Syntec 22TA

FANUC 0i-TF plus

Siemens 828d

Mitsubishi

Application

● Precision parts

● Mechanical parts

● Hardware parts

● Hand tools

● Medical parts

● Clock & watch parts

● Optical parts

● Auto parts

● Bathroom parts

● Bike accessory

Automatic Parts Feeder

Adopting hydraulic system drive, the feeding force is large, suitable for larger diameter and heavier bar material feeding. It has the advantages of good stability and high reliability.

● Improve production efficiency

● Reduce production cost

● Improve production safety

Bar Catcher

Utilizes compressed air as a power source to achieve the splicing function.

● Realizes continuous machining

● Convenient workpiece handling and storage

Automatic Loading Truss

Gripping mode: gripping, handling, lifting, turning

Suitable for:Hardware fittings, plastic parts, 3C electronic parts, automobile parts, electronic and electrical parts, furniture and home appliance parts.

Robot

High precision and high beat rate: with a repeatability of ±0.02 mm and a maximum beat rate of 4 m/s, the robot can efficiently transport parts, increasing productivity by 20% - 40% in machine tool loading and unloading.

Robot loading and unloading: a production line, a single investment can meet the needs of multi-variety production.

Low investment and quick return: one robot can realize single or multi-station loading and unloading.

Turret

The power cutter disc indexing adopts servo cutter disc.

Can cut in forward and reverse directions.

Two-way nearby tool change, fast speed and high efficiency.

High positioning accuracy and high repeat positioning accuracy.

High rigidity and good stability

8 T Servo Turret

12T Power Turret

12T Power Turret With Y Axis

Automatic lubrication

The automatic lubricator automatically delivers lubricant to the X- and Z-axis guide and screw to ensure smooth operation at all times.

In case of oil shortage, an alarm is issued and the machine stops automatically.

| Item | unit | GV400 | GV500 | |

| Max rotary diameter | mm | Φ550 | Φ550 | |

| Max turning diameter | mm | Φ350 | Φ450 | |

| Max turning length | mm | 400 | 500 | |

| Spindle head type | ISO A2-6 | ISO A2-11 | ||

| Chuck size | 12″中实 | 15″solid | ||

| Spindle speed range | r/min | 4000 | 4000 | |

| Spindle through-hole diameter | mm | Φ67 | 60 | |

| Spindle power | kw | 22 | 15KW | |

| Spindle head type | ISO A2-6 | ISO A2-8 | ||

| Chuck size | 12″solid | 12″solid | ||

| Spindle speed range | r/min | 4000 | 4000 | |

| Spindle power | kw | 15 | 22 | |

| Rapid traverse speed | m/min | X=20 X1=20 Z=0 Z1=20 | X=20 X1=20 Z=0 Z1=20 | |

| Maximum travel of XYZ axis | mm | X=530 X1=750 Z=550 Z1=550 | X=580 X1=900 Z=860 Z1=860 | |

| Positioning accuracy | mm | (X)0.008(Z)0.008 | (X)0.008(Z)0.008 | |

| Repeat positioning accuracy | mm | (X)0.004(Z)0.004 | (X)0.004(Z)0.004 | |

| Reverse Difference | mm | 0.007 | 0.007 | |

| Roundness | mm | 0.004 | 0.004 | |

| Cylindricity | mm | 0.012 | 0.012 | |

| Machining flatness | mm | 0.0135 | 0.0135 | |

| Number of turret stations | 8 T | 12T power turret | ||

| Tool change time (adjacent/furthest) | s | 0.45/1.45 | 0.45/1.45 | |

| External shank size | mm | 25×25 | 25×25 | |

| Dimensions of internal hole shank | mm | ≤φ40 | ≤φ40 | |

| X/Z axis guideway type | Ball Guide | X = 45 X1 = 45 | X = 45 X1 = 45 | |

| Z = 45 Z1 = 45 | Z = 45 Z1 = 45 | |||

| X/X1/Z/Z1 axis guideway center spacing | mm | 280/280/600/600 | 280/280/600/600 | |

| X/Z axis screw type | Ball screw | X=φ4010 X1=φ4010 | X=φ4010 X1=φ4010 | |

| Z=φ4010 Z1=φ4010 | Z=φ4010 Z1=φ4010 | |||

| NO. | Standard | Remark |

| 1 | Guangshu 988TD CNC system | |

| 2 | Linear guide | |

| 3 | A206WS | CTB electric spindle |

| 4 | A206WS | CTB electric spindle |

| 5 | Hydraulic station | |

| 6 | 12″ solid hydraulic chuck | 2个 |

| 7 | Taiwan eight-station hydraulic servo turret | 2个 |

| 8 | Chip collection tank | |

| 9 | Electrical cabinet heat exchanger | |

| 10 | Warning light | |

| 11 | Machine tool lighting | |

| 12 | Semi-closed loop measurement | |

| 13 | Inner sliding door protection |

OPTIONAL

MACHINE LAYOUT

the perfect solution for your needs