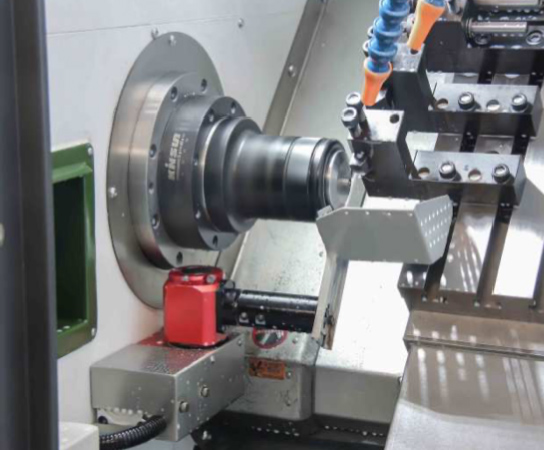

CM300 Griding and Milling and Turning Machine Tool

The base of the machine tool is made of artificial granite. Its excellent shock absorption ensures excellent surface quality of the grinding workpiece and extends the service life of the grinding wheel, thus reducing non-processing downtime. The X direction of the machine tool adopts closed-loop control of linear motor and grating ruler. This control method has extremely high positioning accuracy, while avoiding the wear problems caused by traditional driving methods, helping customers to control dimensions more easily. The spindle and grinding wheel spindle use dynamic and static piezoelectric spindles, which have high efficiency and fast response speed, reduce transmission links, and can achieve high-speed turning and grinding. It has the remarkable characteristics of high speed, strong rigidity, high precision, small thermal deformation, smooth operation and low noise. The machine tool adopts rear brow discharge, which has a large chip discharge space and a smooth chip discharge channel, which can meet the needs of large-capacity iron brow discharge. Depending on your needs, you can choose between manual or automatic eyebrow rowers.

| Availability: | |

|---|---|

1. The X.Z-axis motion axis uses a servo motor to directly drive a precision ball screw pair, and the angular contact screw is supported by a special precision bearing. The pre-stretched structure improves the rigidity and thermal deformation resistance of the screw, and greatly improves the feeding accuracy.

2. Both the X and Z axes are driven by rolling guide rails to ensure smooth transmission and precise transmission accuracy.

3. The machine tool is equipped with GSK/HNC system, which has complete functions, easy operation, stable accuracy and reliable operation.

4. The modular design of the machine tool's bedside box, after finite element analysis, has an advanced and reasonable structure and strong pertinence.

5. The main grinding wheel spindle adopts an electric spindle, which has high efficiency and fast response speed. It reduces transmission links and can achieve high-speed turning and grinding. It has the remarkable characteristics of high speed, strong rigidity, high precision, small thermal deformation, smooth operation and low noise.

CNC Control System Brand

GSK988TA is Standard

Optional:

HNC-808D-10G

Syntec 22TA

FANUC 0i-TF plus

Siemens 828d

Mitsubishi

Application

● Precision parts

● Mechanical parts

● Hardware parts

● Hand tools

● Medical parts

● Clock & watch parts

● Optical parts

● Auto parts

● Bathroom parts

● Bike accessory

Automatic Parts Feeder

Adopting hydraulic system drive, the feeding force is large, suitable for larger diameter and heavier bar material feeding. It has the advantages of good stability and high reliability.

● Improve production efficiency

● Reduce production cost

● Improve production safety

Bar Catcher

Utilizes compressed air as a power source to achieve the splicing function.

● Realizes continuous machining

● Convenient workpiece handling and storage

Automatic Loading Truss

Gripping mode: gripping, handling, lifting, turning

Suitable for:Hardware fittings, plastic parts, 3C electronic parts, automobile parts, electronic and electrical parts, furniture and home appliance parts.

Robot

High precision and high beat rate: with a repeatability of ±0.02 mm and a maximum beat rate of 4 m/s, the robot can efficiently transport parts, increasing productivity by 20% - 40% in machine tool loading and unloading.

Robot loading and unloading: a production line, a single investment can meet the needs of multi-variety production.

Low investment and quick return: one robot can realize single or multi-station loading and unloading.

Turret

The power cutter disc indexing adopts servo cutter disc.

Can cut in forward and reverse directions.

Two-way nearby tool change, fast speed and high efficiency.

High positioning accuracy and high repeat positioning accuracy.

High rigidity and good stability

8 T Servo Turret

12T Power Turret

12T Power Turret With Y Axis

Automatic lubrication

The automatic lubricator automatically delivers lubricant to the X- and Z-axis guide and screw to ensure smooth operation at all times.

In case of oil shortage, an alarm is issued and the machine stops automatically.

Clamping

Collet

Chuck

Size: 6", 8", 10", 12", 15"

Type: solid/ hollow

Jaw: 2/3/4Jaws

Indexing Chuck

| Main Technical Parameters | CM300 |

| Maximum workpiece length | 800mm |

| Grindable cylindrical diameter | Φ8~ Φ300mm |

| Maximum travel of X-axis | 200mm |

| Maximum travel of Z-axis | 1100mm |

| Spindle type | A2-5 |

| Rated spindle speed | 0-1500r/min |

| Chuck type | 8 inch solid chuck |

| Type of tool holder | 12-station power turret |

| X-axis rapid traverse speed | 20m/min |

| Z-axis rapid traverse speed | 20m/min |

| Center height | 190mm |

| Maximum weight of workpiece to be ground | 150kg |

| Maximum turning angle | -3°~ +3° |

| Size of grinding wheel | Φ600x(20~75)xΦ305mm |

| Grinding wheel linear speed | 45m/s |

| Tailstock sleeve taper hole is Morse taper | 5# |

| Maximum travel of tailstock center sleeve | 100mm |

| Roundness | 0.002mm |

| Consistency of internal dimensions in longitudinal section | 0.002 mm/100mm |

| Surface roughness | ≤Ra0.4um |

| X/Z axis repeatability | ≤0.002mm |

| Cylindricity | 0.002mm |

| Runout error | ≤0.002mm |

| Dimensional accuracy of machined journal | ±0.001mm |

| Spindle head motor power | 4.7KW |

| Power of wheelhead motor | 15KW |

| Overall dimensions of machine | 4250x2580x1800 |

Standard configuration

Bed Artificial granite casting

Spindle box, drag plate, etc. Integral resin sand casting

CNC control system HNC-808DiT

Feed drive, motor HNC

Spindle ZZDY20 spindle unit

Tailstock φ95 tailstock shaft

Z ballscrew Hiwin

X Ball screw THK

Z Linear guideway Hiwin

X Linear Guideway THK

Turret Taiwan Lianji 12-station power turret

Oil mist absorber Xinxin

Measuring Instrument Centaline Precision

Row Cutting Machine Xinke Yang

Optional

MACHINE LAYOUT

the perfect solution for your needs